When traveling uncharted roads, having a map can make the difference between getting lost and finding your way. A plan for troubleshooting, like a map, can help guide you to an equipment malfunction. Made up of a logical sequence of troubleshooting steps, this troubleshooting map can help the technician hunt down the defect in a piece of electronic communication equipment. By developing and using this strategy, the technician can become very proficient at locating electronic problems and repairing them. After completing this article, you should be able to

- Describe the purpose of the inspection

- State the sequence of troubleshooting steps

- Troubleshoot an RF amplifier and oscillator

- Check for transmitter operation on proper frequency

- Correct for low transmitter output power

Inspection | Radio Transmitter Troubleshooting

The first phase of any repair action is to do a visual inspection of the defective equipment. During this inspection look for broken wires, loose connections, discolored or burned resistors, and exploded capacitors. Burned resistors are easily seen and will give off a distinguishing odor. Equipment that has been dropped may have a broken PCB (printed circuit board). Connectors may have been knocked loose. Look for bad soldering and cold solder joints. Cold solder connections look dull and dingy as opposed to nice shiny good ones. Intermittent faults are usually the result of cold solder joints. Components hot to the touch after the equipment has been on for a few minutes can indicate shorted components. Listen for unusual sounds when the equipment is turned on. Unusual sounds could lead you to the malfunctioning component. Many defects are found during this inspection phase and the equipment frequently gets fixed without further troubleshooting.

Strategy for Repair | Radio Transmitter Troubleshooting

VERIFY THAT A PROBLEM DOES EXIST | Radio Transmitter Troubleshooting

Always verify that the reported problem exists before troubleshooting the equipment. By confirming the problem, you will save time that could get wasted looking for a nonexistent defect. If the equipment is not completely dead, try to localize the symptom to a particular stage. Check the service literature for troubleshooting hints. Some manufacturers provide diagnostic charts to help pinpoint malfunctions. The more clues you gather the more apt you are to successfully associate a fault to a particular circuit function. Another reason for confirming that the problem exists is to rule out operator error. The equipment owner or operator may not know all the equipment’s functions and may consider the unit bad if it can’t do something it wasn’t designed for. Check the operating manual when in doubt about the equipment functions.

ISOLATE THE DEFECTIVE STAGE | Radio Transmitter Troubleshooting

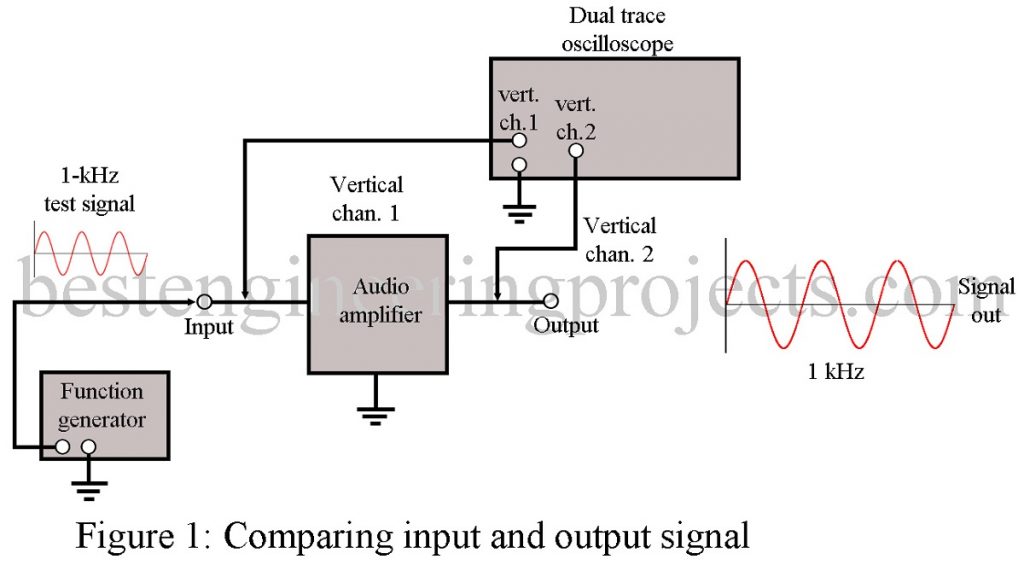

When a problem has been verified in a piece of electronic equipment, begin troubleshooting to isolate the defect to a particular stage. Normally the defective stage can be found by signal tracing or signal injection. The oscilloscope can be used with either the signal tracing or signal injection method. A signal generator or a function generator are used to supply a test signal at the input of the specific stage under examination. Figure 1 illustrates a dual trace oscilloscope connected to an amplifier stage to show the input test signal and the output signal. The input signal is easily compared to the output signal with this test setup. If the output signal is missing or distorted, then the defective stage has been located.

ISOLATE THE DEFECTIVE COMPONENT |Radio Transmitter Troubleshooting

Once the defective stage has been located, the next step is to find the bad component or components. Voltage and resistance measurements should be used to locate the defective component. Remember, voltage measurements are made with respect to ground, and resistance measurements are done with the power off. The voltage and resistance measurements are compared to specified values stated in the service literature. Incorrect readings usually pinpoint the defective component. It is very possible that there may be more than one bad component in a malfunctioning circuit.

REPLACE THE DEFECTIVE COMPONENT AND HOT CHECK | Radio Transmitter Troubleshooting

Before replacing the bad component in a circuit, make sure that another component is not causing it to go bad. For example, a shorted diode or transistor can cause resistors to burn up. Diodes and transistors should be checked for shorted conditions before associated components are replaced. Replace defective components with exact replacement parts. Once the defective component is replaced, ensure that the circuit is operating normally. You may need to do a few more voltage checks to confirm things are back to normal. Burn-in the equipment by turning it on and letting it operate a number of hours on the test bench. This burn-in is a vital part of equipment repair. If failure is going to reoccur, it will usually show up during this burn-in period.